Getting our customers wagons back on the tracks as quickly as possible – that´s one of our main priorities for overhauls and maintenance. For that, we rely on our extensive network of partner workshops. But what if we were to expand this network – to our customers’ premises? That’s exactly what we did with our French customer Arkema.

Taking the opportunity

It all started in 2020, when we signed a lease agreement with chemical manufacturer Arkema for 36 chemical rail tank cars assigned to the transport of cyclododecane – that´s an industrial material, which is mainly used for making certain types of plastics or coatings.

Better safe than sorry:

Cyclododecane is a waxy, solid substance that becomes liquid at higher temperatures. As for transport, chemicals like cyclododecane are shipped in rail tank cars designed to handle its solid or liquid form, ensuring it stays stable and safe.

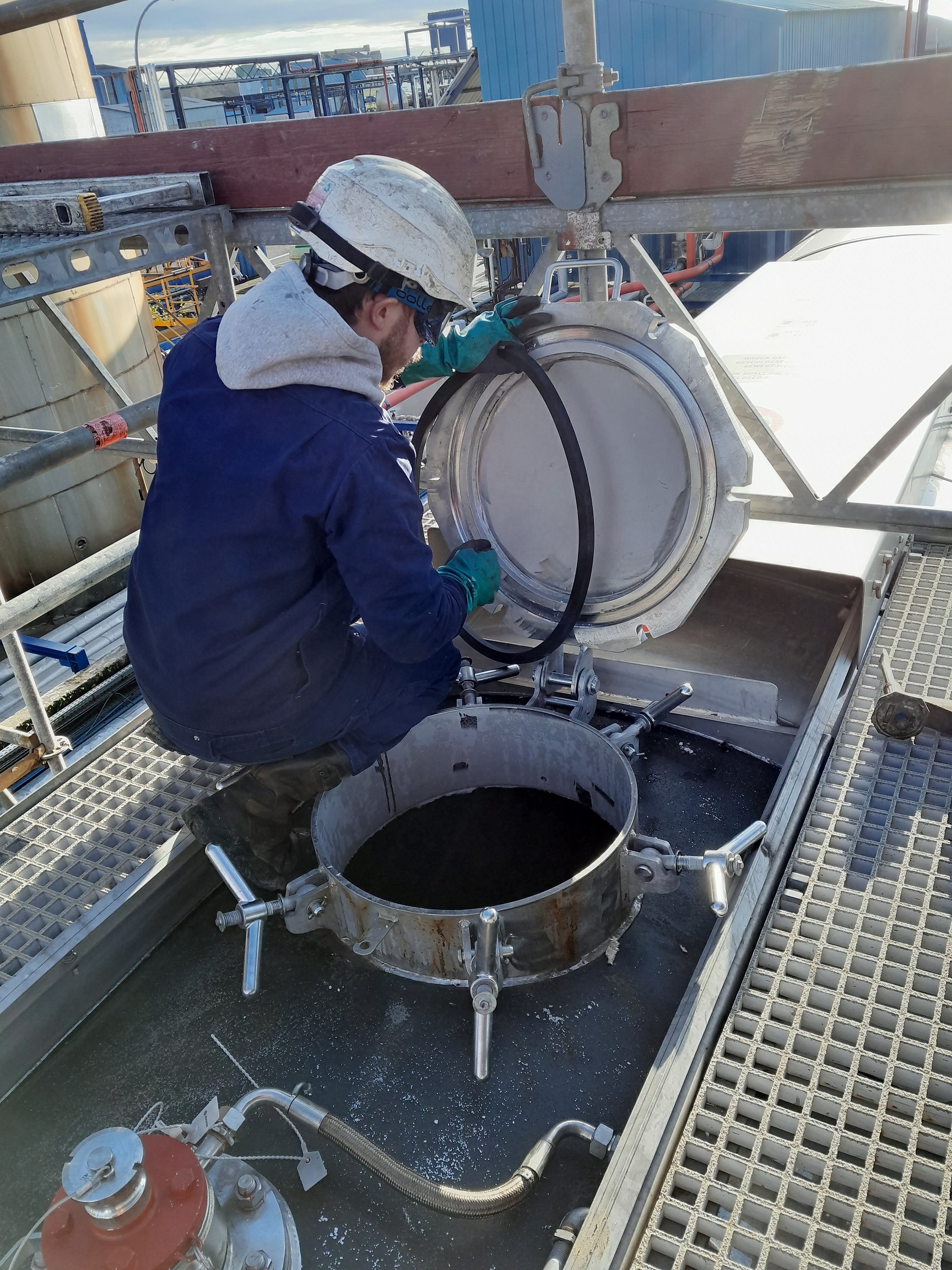

These wagons (type C52.088.28D), whose design was developed in close cooperation with the customer, were then built by Waggonbau Graaf in 2021. But it didn’t end there: Together with Arkema, we decided to use the opportunity to work even more closely together on the subject of overhaul and maintenance and developed a special mobile maintenance platform at the customer´s site in Mont (south of France).

Rethinking maintenance

The idea is simple but offers both the customer and us several advantages: Bringing overhaul and maintenance services directly to the customer´s site to not only allow the customer to save money but to gain availability, too, as there is no need to return the wagon to a workshop. Furthermore, the loss of operation of the wagon is limited to a few days instead of several weeks.

And of course there are many advantages for us, too: We free up capacity in the workshops and benefit from a concrete marketing advantage compared to our competitors who do not offer this type of service.

All in all, this project is an important step for us, and it strengthens our ties with Arkema by reinforcing the customer’s confidence in the innovations provided and the after-sales service provided by VTG.

Built on expertise, made possible by cooperation

Only through the extensive and long-standing experience of our colleagues at the mobile teams of Ateliers de Joigny as well as the technical service of VTG Rail Europe France, this type of very ambitious service could be realized! Furthermore, cooperation was key in the realization of the project, for example with our safety colleagues and the various departments who are responsible for rail tank cars.

Consequently, there is absolutely no question that this project would not have been possible without the cooperation and the input of resources and knowledge from a wide range of VTG departments – thank you to …

- … Waggonbau Graaf

- … various Market France services

- … Hamburg Support Services

- … mobile teams from Ateliers de Joigny/AMSO

We would also like to thank our partners who contributed to the success of the on-site maintenance service:

- Arkema Mont

- Ateliers de Joigny

- VTG Security Service OT-S France

- VTG Rail Europe France technical service

More impressions from Mont:

Do you like the story?

Comments on the post

Sylvie BAYLE

TOP Joffrey - Excellent article sur la Maintenance mobile. Merci également à tous les partenaires qui ont contribué au succès de ce projet.

Nathalie MARIE

Thank you Joffrey, you made it possible !

Thierry

Well Done. What an inspiring example of customer centricity !

Nadia CORDELLA

Un bel article ! Félicitations à Joffrey, AMSO (Ateliers de Joigny) ainsi qu'aux partenaires.

Julie MARGOT

Proud of you !

Friederike Froehlich

More of these!

Jérémy THOMAS

Great job !

Kim LE MAITRE

Very interesting read! Well done Joffrey and AMSO (Ateliers de Joigny)!

Anne-Marie Guillard

Very interesting Joffrey. And good cooperation between you, technical service, mobile team Joigny and customer